Wood coatings

Wood is one of the most preferred materials in the construction, furniture, and decorating industries due to its natural beauty and environmental friendliness. However, to protect it from wear, moisture, mechanical damage, and harmful environmental influences, it is necessary to apply coatings that can also emphasize the texture and color of the wood. In this article, we'll take a look at the main types of wood coatings, methods of applying them, and key aspects of wood care.

Types of wood coatings

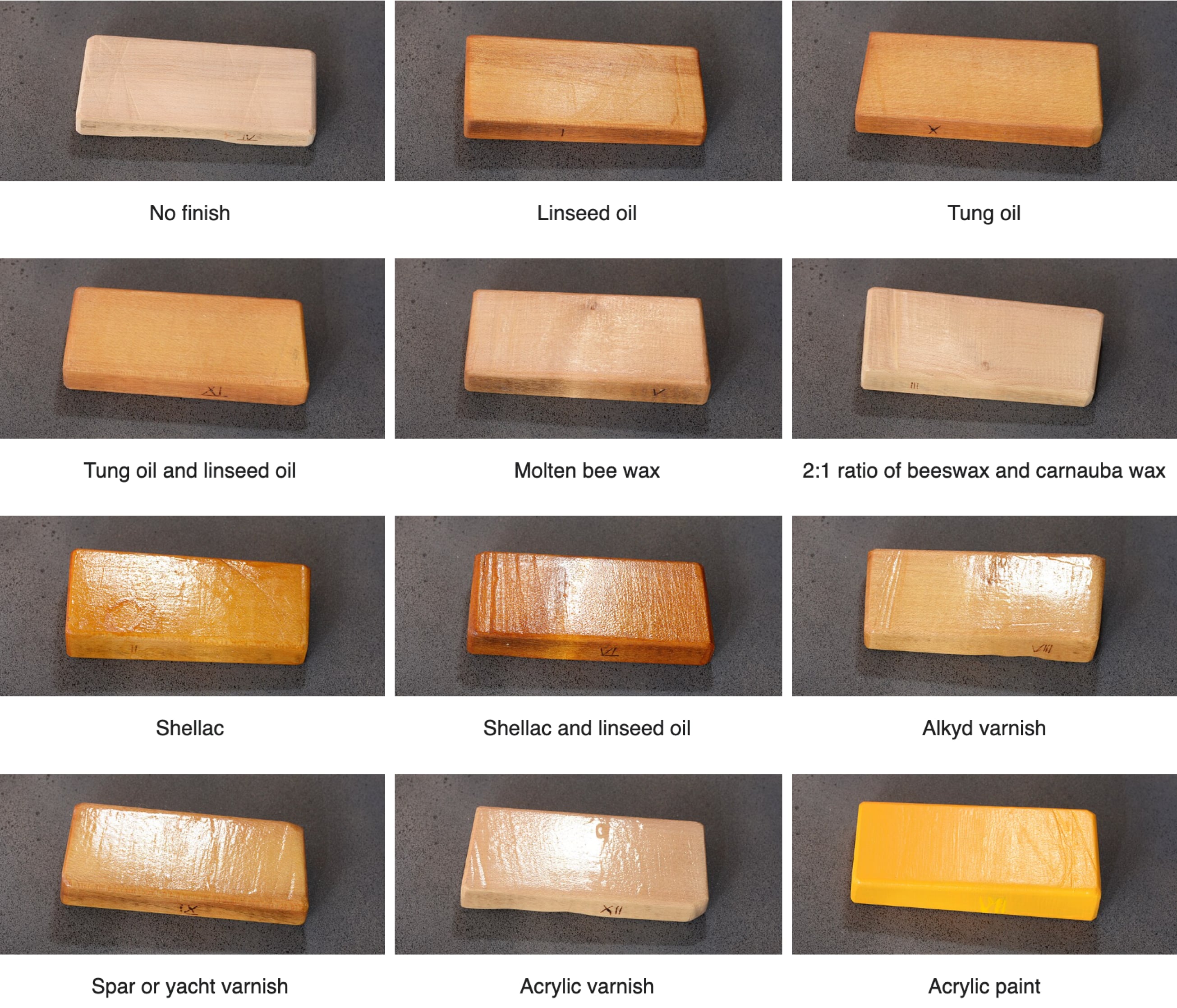

Photo: Wood finishing

Varnishes

Varnishes create a protective layer on wood that ensures durability and aesthetics. They are suitable for interior and exterior use and are available in water or solvent formulations. Water-based varnishes are environmentally friendly, dry faster and have a low content of volatile organic compounds (VOCs), but are inferior to solvent-based varnishes in terms of moisture resistance.

– Appearance: liquid, transparent, or translucent. After drying, their texture is usually smooth and hard. When applied, they are watery, spread quickly, and fill wood pores well.

– Suitable for: floors, furniture, decorative elements, wooden walls and stairs.

– Color: transparent or with a slight tint. Some varnishes are available in color variations to create a tinted effect.

– Application methods: brush, roller, pneumatic spraying or manual rubbing.

Shellac

Shellac is a natural product derived from the resin of lacquer worms Laccifer lacca. For use, it is mixed with ethyl alcohol to create a coating with a beautiful gloss that emphasizes the wood grain. It has excellent adhesive properties, is UV resistant and environmentally friendly.

– Appearance: sticky and thick in liquid form, after drying it forms a smooth, shiny and hard layer.

– Suitable for: furniture, musical instruments, decorative panels, restoration work.

– Color: natural shade from light yellow to amber.

– Application methods: brushing, manual rubbing or pneumatic spraying.

Stains (beitz, from German: beize)

They give the wood the desired shade while preserving its natural texture. They penetrate the pores of the wood, changing its colour, but do not create a protective layer. Stains are often used in combination with varnishes or waxes to enhance durability and decorative effect.

– Appearance: a liquid texture that leaves behind a natural wood look.

– Suitable for: furniture, floors, decorative panels.

– Colour: natural shades, from light to dark.

– Application methods: spraying, rubbing, dipping, brushing and roller application.

Paints

Wood staining creates a dense, opaque coating that protects the surface from external influences and adds colour. Paints are divided into acrylic, alkyd, oil and latex. Acrylic paints dry quickly and do not have an unpleasant odour, while alkyd paints provide long-term resistance to mechanical damage.

– Appearance: thick, creamy texture. After drying, it forms an even matte, semi-matte or glossy surface.

– Suitable for: furniture, building facades, doors, window frames.

– Colour: available in a wide range of shades.

– Application methods: spraying, electrostatic centrifugal method, pouring, vacuum application, manual, drum application, using rollers, brushes, etc.

Oil coatings

Oil-based wood finishes are made from natural oils such as linseed, tung, Danish or a combination of these. They penetrate into the pores of the wood, protecting it from the inside and preserving its natural texture and appearance. Oils give wood water-repellent properties, but do not form a dense outer layer, so they are suitable for moderate use.

– Appearance: a liquid, sometimes slightly thick texture that is easily absorbed into the wood. After drying, the surface remains matte or with a slight sheen, with a natural feeling of smoothness.

– Suitable for: furniture, worktops, kitchen boards, toys, parquet and decorative panels. It is also used for exterior wooden structures if re-applied.

– Colour: transparent, sometimes with a warm yellowish tint. Can be tinted for an additional effect.

– Application methods: with a cloth, sponge or brush, manual application, polishing for even distribution. A roller is used for large surfaces and a dipping method for small details.

Oil-wax

This is a combination of natural oils and waxes that creates a soft, shiny layer that highlights the wood grain. This coating is easy to apply by hand and is suitable for furniture, floors and decorative products in rooms with moderate humidity.

– Appearance: oily, slightly thick texture. After drying, the surface has a soft gloss with a natural smooth feel.

– Suitable for: furniture, decorative panels, and floors in rooms with low humidity.

– Colour: natural transparent or with light shades (depending on the composition).

– Application methods: with a cloth or sponge, brushing, roller application, polishing with a polishing machine, dipping method for small items.

Polish

A polish is an alcohol-based varnish containing 10-20% by volume of a film-forming substance.

It creates a thick protective layer with high resistance to wear and weathering. It is used for exterior and interior work, often on surfaces with high loads.

– Appearance: viscous liquid, after drying - smooth and shiny surface.

– Suitable for: floors, furniture, window frames, and doors.

– Colour: transparent or with a slight tint.

– Application methods: brushing, swabbing, spraying, roller application, manual polishing with a cloth, machine polishing.

Polyurethane

Polyurethane is a type of varnish that contains specific polyurethane resins as the main binders. It creates a strong protective layer that is resistant to scratches, wear, moisture and chemicals. Aqueous polyurethanes are more environmentally friendly, while solvent-based polyurethanes provide higher resistance and durability.

– Appearance: liquid during application, after drying the surface becomes smooth and hard, with varying degrees of gloss (glossy, matte).

– Suitable for: floors, kitchen worktops, and furniture.

– Colour: transparent, available in different gloss levels.

– Application methods: brush application, roller application, spraying with a spray bottle, application with a cloth (wiping), dipping (for small products), pouring with a spatula, and machine application on production lines.

Dye

A colouring agent is a substance used to give wood a certain colour or shade. Dyes can be natural (derived from plants, minerals or animals) or synthetic (chemically created). They penetrate the structure of the material, providing a stable and durable colour.

– Appearance: liquid, easily penetrates the surface of the wood, creating a uniform shade.

– Suitable for: furniture, and decorative elements.

– Colour: a wide range of shades, depending on the composition.

– Application tools: sponge, cloth, brush or spray.

French polish

French polish is a shellac application technique that creates a thin, multi-layered protective layer with a mirror-smooth surface. The coating is formed by repeatedly applying a shellac solution in combination with a lubricant that reduces friction during rubbing. This method is labour-intensive but provides a unique aesthetic result.

– Appearance: a thin layer with a high gloss and smooth texture. After the process, the surface resembles a mirror. The coating is very thin, which allows you to preserve the natural texture of the wood.

– Suitable for: antique furniture, musical instruments (in particular, violin and guitar bodies), decorative panels and artistic products.

– Colour: warm shade, depending on the colour of the shellac. Most often from light amber to dark amber.

– Application tools: tampon application (tamping), layered application, rubbing in oil before polishing, and finishing polishing. In the process, a lubricant, such as linseed oil, is added to prevent the swab from sticking to the surface.

Water-based coating

Water-based coatings are environmentally friendly water-based finishing materials used to protect and decorate surfaces. They are suitable for interior use and create a transparent protective layer.

– Appearance: liquid, watery texture, forms a smooth, transparent surface after drying.

– Suitable for: furniture, floors, and decorative items.

– Colour: transparent or with a slight tint.

– Application methods: brush, roller, spraying with a spray bottle, dipping, pouring with a levelling spatula.

Methods of coating application

Pneumatic spraying

A professional method that allows you to quickly apply coatings over large areas, ensuring the uniformity of the layer. It is used for varnishes, paints, polyurethanes and other liquid materials. This method is ideal for furniture, doors and large structures. Its advantage is speed and quality, but it requires special equipment.

Immersion

An effective method for small parts and products that need to be coated from all sides. The elements are completely immersed in the liquid, which ensures uniform application even on difficult surfaces. The method is used in the production of furniture, doors and fittings.

Drum coating

An innovative method for processing small parts such as handles or fasteners. In a special drum, the parts rotate together with the coating, which is evenly distributed over their surface. This approach is often used in the furniture industry.

Modern technologies (UV-curing)

Polymeric coatings that allow for quick application and curing of the coating using ultraviolet radiation. This approach is often used in the production of parquet or furniture. It reduces the drying time to a few seconds and provides a high level of wear resistance.

Manual rubbing

It is used for natural oils, oil-wax mixtures or stains. The coating is rubbed into the wood surface with a cloth or sponge. This method ensures deep penetration and emphasises the texture of the material.

Brush

It is used for applying varnishes, paints or oils, which allows you to evenly distribute the material on the surface. The main disadvantage is the possibility of smear marks that require additional sanding.

Drying time of coatings on wood

– Varnishes: from 6 hours to three days. Oil-based varnishes and water-based formulations usually take longer to dry, while alcohol and nitrocellulose varnishes take 20-30 minutes.

– Shellac: up to 24 hours for complete drying, although this time may be shorter on surfaces without strong absorption.

– Oil-wax: up to 72-96 hours for complete drying. This is the time to achieve full stability of the coating, although the surface may be dry after a few hours.

– Paints: Acrylics - usually about 2 hours to dry, as opposed to alkyd paints, which take 12 to 24 hours to dry depending on the thickness of the layer and environmental conditions.

– Stains: 1 to 24 hours to dry depending on the type and conditions, water-based stains usually 2-3 hours.

– Polyurethane: 2 to 6 hours at an average room temperature of +20°C to achieve a dry surface, but may take longer to dry completely.

– Dye: 1-2 hours for drying, depending on the type and thickness of the layer.

– Waterborne coating: 24 to 48 hours for complete drying, depending on the layer thickness and environmental conditions.

Care for wood flooring

Regular cleaning

Use mild detergents without abrasive particles to prevent damage to the surface. Regular cleaning prevents the accumulation of dirt and dust, which can damage the finish. Avoid harsh chemicals as they can cause the coating to fade or break down.

Repair and renewal

Periodically inspect wooden surfaces for scratches, cracks or other defects. If the surface is damaged, renew the coating layer as necessary to restore its protective properties and appearance. Renewal may include applying an additional coat of varnish, oil or wax to provide long-lasting protection.

Protecting exterior surfaces

For exterior wooden structures (e.g. garden furniture or wooden facades), use sealants and regular cleaning to protect the wood from the negative effects of weather conditions such as moisture, UV radiation and temperature changes. This will help preserve the natural appearance and durability of wooden surfaces.

Specialised care

For complex objects, such as stairs, decks or decorative elements, professional treatment is recommended, which includes the use of special products for long-term protection of wood from moisture, dust and mechanical damage. These treatments provide a higher level of protection and extend the service life of wooden surfaces in harsh environments.

Coatings for the durability of wooden products

The right choice of wood coatings, application methods and regular maintenance will help to keep wood in excellent condition for many years. It is important to take into account the type of wood, operating conditions and the desired aesthetic appearance to find the perfect solution for your needs.

Each wood finish has its characteristics, so choosing the right care and maintenance products will not only improve the appearance but also extend the life of your wood product. By investing in quality finishes and care, you can enjoy the natural beauty of wood and its durability, while maintaining its functionality and appeal for many years.

Leave your feedback Cancel reply