Wooden F1 Paddock

For several decades, global architecture has been moving towards environmental friendliness, engineering precision and visual expressiveness. But when innovation reaches such large-scale international events as Formula 1, the status of environmentally friendly materials changes dramatically. The new paddock at the Canadian Grand Prix is a prime example of how wood is no longer a “traditional” material but has moved into the category of high-tech structures that meet the requirements of modern sports infrastructure.

The wooden structure of the paddock in Montreal is not just an architectural gesture or a design experiment. It is proof that wood can combine strength, speed of construction, adaptability and environmental friendliness even in the context of high-load structures that serve Formula 1 teams, international media and thousands of guests.

Unique architecture amid the roar of racing cars

The Canadian Grand Prix paddock is located at the Circuit Gilles-Villeneuve racetrack on the artificial island of Notre Dame in Montreal, a place where tens of thousands of fans and the most powerful Formula 1 teams gather every year.

The building was officially opened on 15 May 2019, becoming one of the most prominent modern structures. The total budget for the project was $59 million ($41 million from the city of Montreal and $18 million from the Quebec government).

One of the key elements of the building is a massive wooden roof made of CLT (cross-laminated timber) panels and glulam (glued laminated timber), which not only reduced the weight of the roof but also increased its environmental potential. The 300-ft (1,425 m³) wooden roof accumulates over 1,000 tonnes of CO₂, reducing the building's overall carbon footprint.

The panoramic terraces on the second and third floors offer views of the highway, the Saint Lawrence River, Jean Drapeau Park and the Casino de Montréal, making the building not only functional but also visually appealing. The project was highly praised by the professional community and received the Award of Excellence from Canadian Architect even before construction was completed.

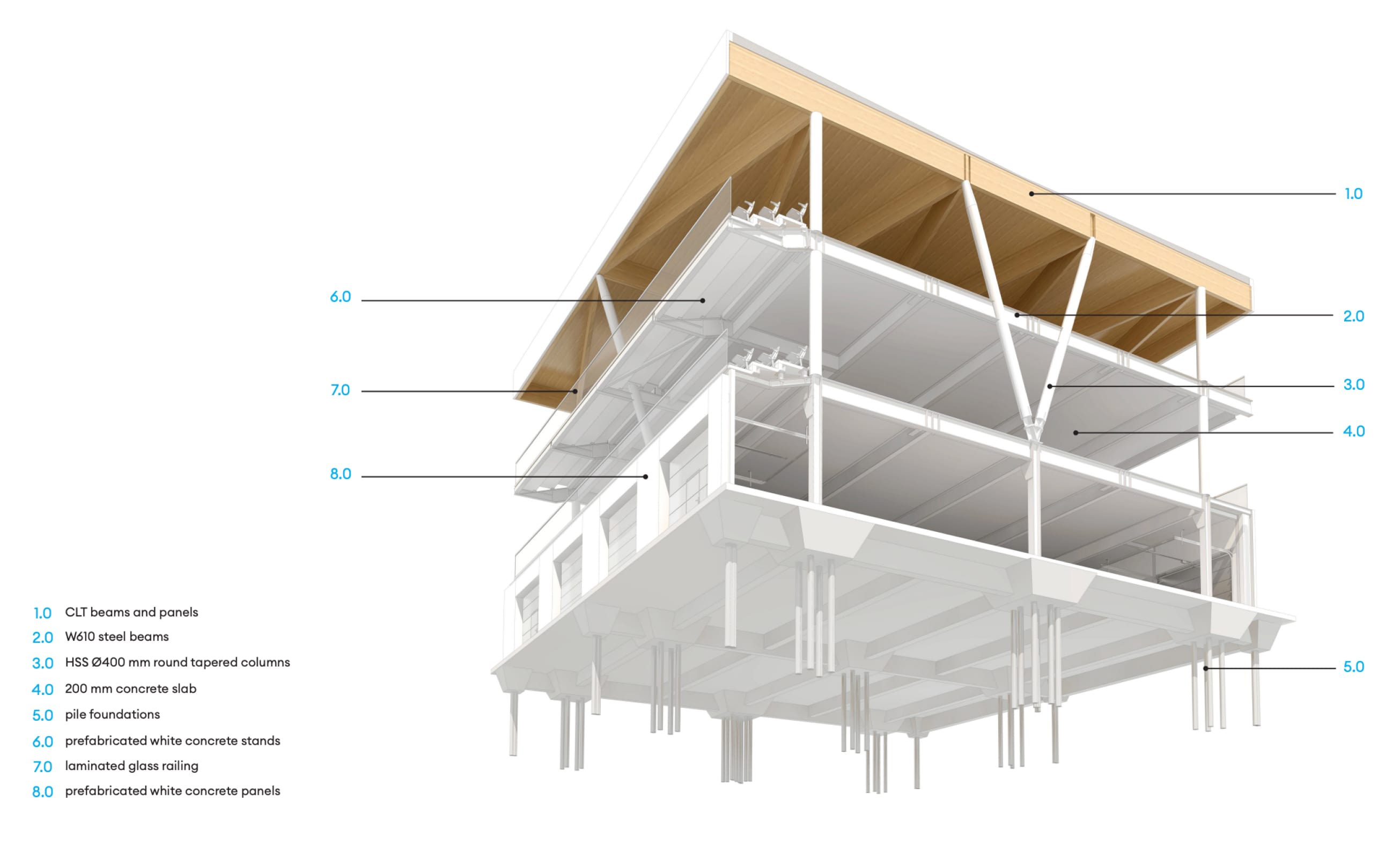

Construction materials

The Canadian Grand Prix paddock is based on wood, a material that is setting new standards in global architecture today. All key load-bearing elements of the building are made of glued laminated timber and CLT panels, construction materials that combine the natural strength of wood with high precision factory production. It is this combination that allows for the construction of a large-scale structure in a short time and ensures its reliability in an area with increased technical loads.

CLT panels are used primarily in the roof and floor slabs. They form a monolithic space without additional metal reinforcements, which reduces the weight of the structure and increases its stability. Such panels provide high rigidity with minimal thickness and also have excellent thermal insulation properties, which is especially important for buildings operating in climates with sharp temperature fluctuations.

Glued laminated timber (glulam) is used in the main frames and load-bearing arches that support the long roof spans. It allows the creation of long elements without the risk of deformation, while preserving the natural appearance and warm aesthetics of wood. Such elements have become a dominant part of the architectural image of the paddock – they are not hidden, but on the contrary, are exposed details of the interior and exterior.

Special attention has been paid to the protection of the wood. All structural elements have a special fire-retardant and moisture-resistant coating that complies with international safety standards and allows the building to withstand large flows of people, mechanical loads and contact with external factors during rainy or cold race days.

Photo: ArchDaily

Construction process

The construction of the Canadian Grand Prix paddock took place within an exceptionally short time frame – during a single Formula 1 off-season. This pace was made possible by the use of a modular system and the prefabrication of all wooden elements at the factory. Glued laminated timber, CLT panels for floors and roofs, as well as metal connecting nodes were delivered to Notre Dame Island ready-made, which allowed the building to be erected quickly and with a minimum amount of work on site, within one off-season.

Assembly began with the installation of massive glued frames that formed the load-bearing structure. After that, CLT panels were sequentially laid on the structure, ensuring the rigidity and stability of the entire system. Thanks to the precise geometry of the factory-made elements, the assembly took place without additional fitting, and the structure itself grew floor by floor at a clearly defined pace.

During construction, great attention was paid to logistics: materials were delivered in strict sequence, and installation teams worked in parallel at different levels. This made it possible to complete the project on a schedule that is rarely possible for structures of this complexity. After the wooden frame was installed, glass and metal façade systems, engineering networks and upper-level terraces were integrated.

Construction team

The Canadian Grand Prix paddock was built through a collaboration between leading architecture and woodworking companies. The architectural concept was developed by Les Architectes FABG, a firm with many years of experience in cultural and public building projects. For example, their Mont-Laurier Multifunctional Theatre project is a theatre building with a wooden structure.

Nordic Structures was responsible for the supply and manufacture of engineered wood (glued laminated timber and CLT), using materials from its glued laminated timber (“Nordic Lam”) and CLT (“Nordic X-Lam”) ranges.

The general contractor responsible for the installation of wooden structures, logistics and system integration was the Canadian construction company Pomerleau.

Photo: Nordic Structures

The future of eco-architecture using wood

The Canadian Grand Prix paddock has demonstrated that modern engineered wood can be used to create ambitious international-level projects that combine scale, strength and environmental friendliness. A hybrid system of glued laminated timber and CLT ensured rapid assembly, structural durability and opened up opportunities for modular approaches, panoramic terraces and open spaces, creating comfortable conditions for teams, spectators and the media. It is important that wood can be not only a decorative element but also the basis of a high-tech structure, demonstrating the synergy of architecture, engineering and environmental friendliness.

The project opens up new horizons for contemporary global architecture, demonstrating that design and engineering approaches to wood are not only relevant but also necessary for the sustainable development of the construction industry. The future of large, technological and at the same time environmentally friendly structures lies in natural wood, which combines aesthetics, safety and functionality on a global architectural scale.

Leave your feedback Cancel reply