Types of wood materials

Wood is one of the most versatile and popular materials in various industries, in particular in construction, furniture industry, automotive and carriage building industries, as a material for packaging products, etc. In this article we will look at the most common types of wood materials and their applications.

1. Solid wood

Solid wood is a natural and natural material. This is a product of cutting logs into lumber and processing them to size without further processing. Solid wood is used to make furniture, kitchen products, wall panels, floors, doors, windows, interior parts and much more.

2. Rubber solid wood

These are glued along the layer or longitudinally to the wood using special adhesives. Fused wood is more resistant to deformation, changes in humidity and retains its shape better than solid wood. It is used for the manufacture of folding furniture, beds, table tops, building elements, etc.

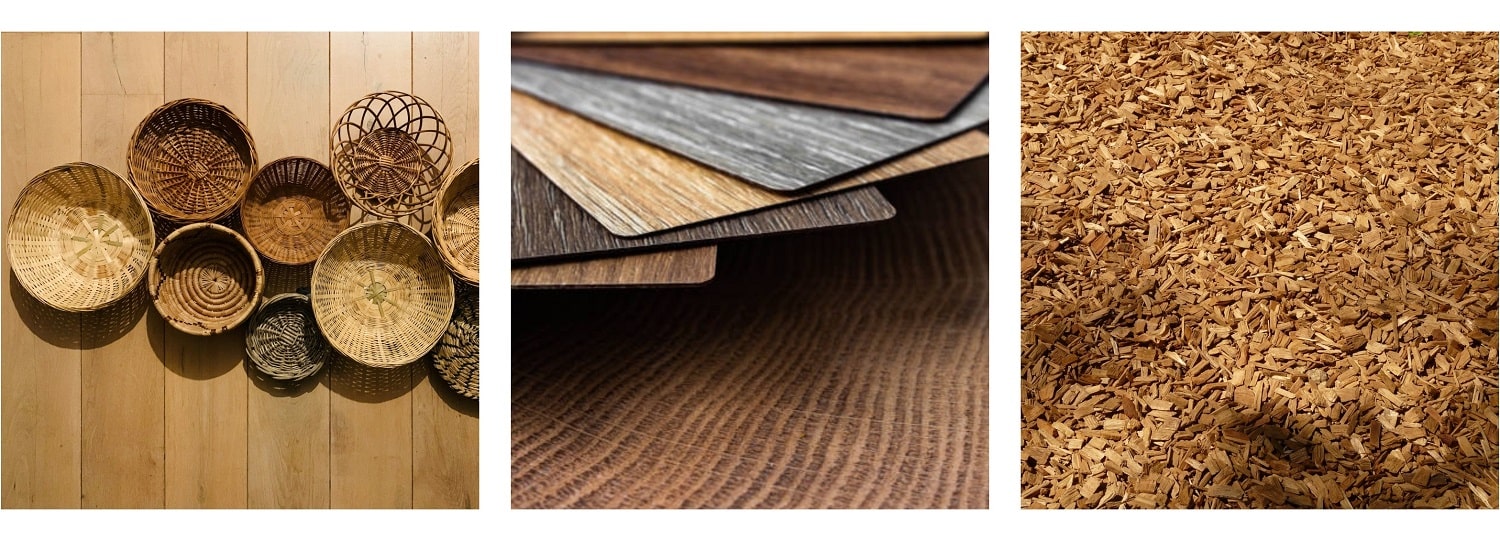

3. Chipboard

It is a glued sheet material made from wood chips and fine particles, bonded together using glue and high pressure using hot flat or extrusion pressing. Used for the production of cabinet furniture, flooring, countertops, wall decoration, etc.

4. Wood fiberboard

The process of making fiberboard involves grinding wood into fibers or particles such as shavings, chips, wood dust, and then mixing it with glue and other additional substances. This mixture is pressed under high pressure and heat to create a uniform sheet. Fiberboard is a popular material in the construction and furniture industry.

5. MDF (Medium Density Fiberboard)

MDF is a type of wood material whose manufacturing process involves grinding the raw material into fibers, after which these fibers are pressed under high pressure and temperature. The main binder in MDF is lignin, a natural polymer found in wood that is responsible for binding the fibers together. MDF is used for the manufacture of furniture facades, doors, wall decoration, decorative items, etc.

6. OSB (Oriented Strand Board)

It is a type of multi-layer wood-based panel material made from wood chips, usually pine, by hot pressing under high pressure and high temperature. Typically used for structural purposes in construction and renovation such as sheathing, flooring and other exterior or interior work.

7. Wood veneer

Veneer is a wood material in the form of thin sheets of wood with a thickness of 0.1 to 10 mm. Made from high-quality wood and used to create aesthetic interiors. Used to cover furniture, doors, interior walls, and for decorative purposes. Wood veneer is one of the most common materials for surface treatment in furniture production.

8. Wood plastics

Wood plastics or wood laminated plastics are plasticized wood materials that are produced by complex mechanical, thermal and chemical processing of raw materials such as peeled veneer, shredded wood and other wood waste. Wood plastics are used as structural, wall and production materials in mechanical and shipbuilding, electrical engineering, construction, etc.

9. Wood-plastic composites (WPCs)

Wood-plastic composites (WPC or WPC, Wood-Plastic Composites) are materials that contain wood flour or fibers that are combined with a thermoplastic polymer such as polyvinyl chloride (PVC), polypropylene or polyethylene, as well as with various modifiers to the finished product. These materials have a number of advantages, such as resistance to external conditions, high strength and dimensional stability. They are used for the manufacture of various products, such as boards, panels, fences, etc., intended for use outdoors under the influence of direct sunlight, with changes in temperature and humidity.

Each type of wood material has its own advantages and disadvantages. The choice of type of wood material depends on the specific needs, properties of the material and its cost. Proper use and processing of wood materials produces high-quality products with a variety of applications in production and everyday life.

Read more about wood products on our blog.

Leave your feedback Cancel reply