Wood waste recycling

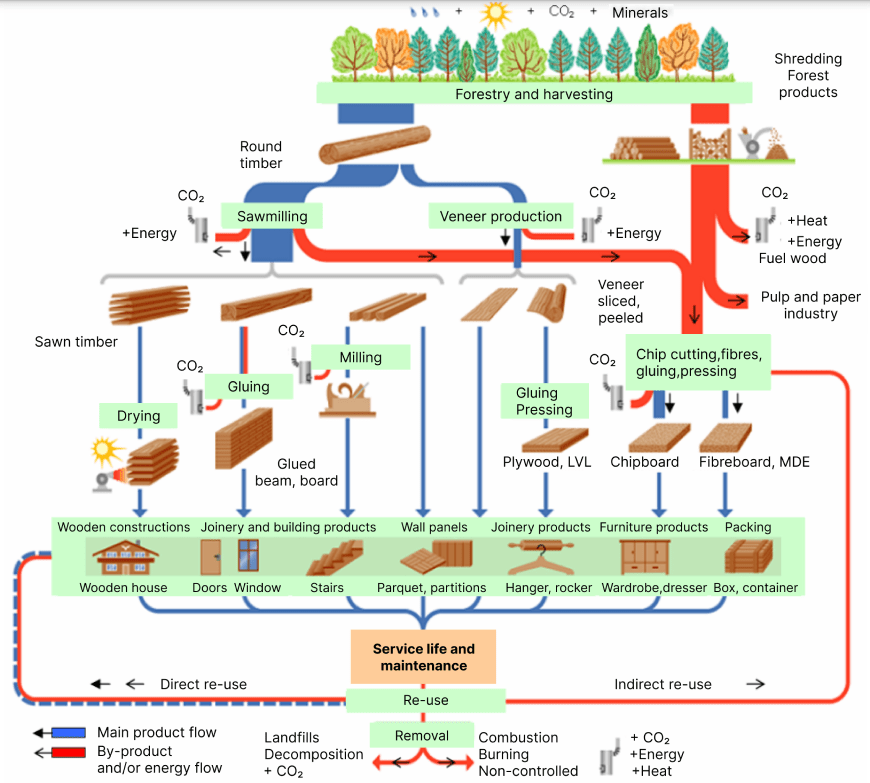

Waste wood is materials or products that lose their original value, purpose and are considered unnecessary or unsuitable for further use. This can include residues from wood processing, such as sawdust, trimmings, chips, as well as deductions from the manufacture of furniture, wooden structures, packaging, etc. Waste wood can also include old furniture, posts and beams from building demolition, or even trees that have been harvested in connection with construction or landscaping.

Globally, construction and demolition waste accounts for nearly 30–40% of total solid waste. Here are some figures on wood waste from construction and demolition:

– In 2018, all 28 EU countries produced around 50 million tonnes of wood waste.

– In 2020, the US generated about 56 million tonnes of wood waste.

– In 2020, Hong Kong alone generated 21 million tonnes of wood waste from construction and demolition.

– Sweden produces about 2 million tonnes of wood waste per year [1].

The treatment and utilisation of this waste is becoming an important component of a sustainable natural resource management and environmental protection strategy. Waste wood (WW), generated from defective products and end–of–life products, is a key source of biomass. Its efficient use contributes to reducing CO2 emissions, making it one of the most important steps in resource use.

In Europe, about 53% of wood waste is incinerated, while 46% is recycled. In Italy, almost 95% of wood waste is used in the production of chipboard and fibreboard. In 2020, the European Union generated more than 48 million tonnes of wood waste. Of this, more than 40 million tonnes were used, accounting for about 83% of the total. Of this waste, about 53% is used for energy production and about 46% is recycled. The rest is taken to landfills or used as backfill.

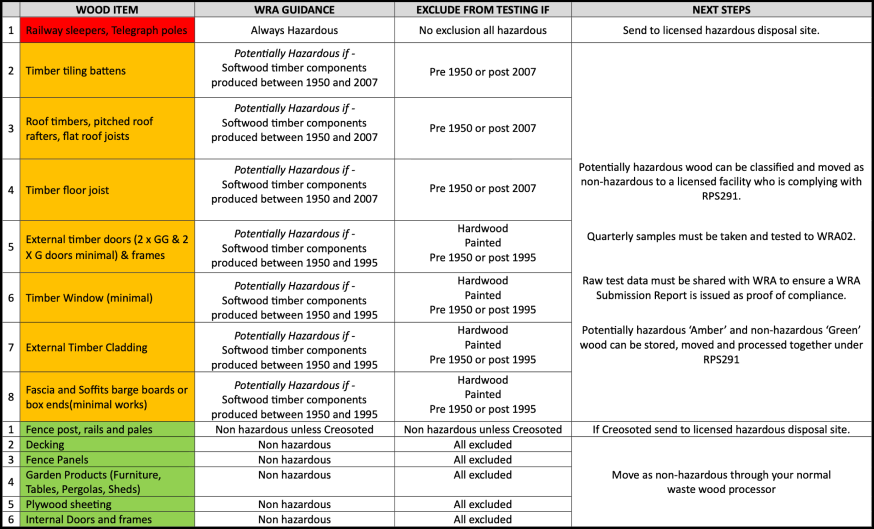

One of the most important areas of wood waste use in Europe is the production of chipboard. Among European countries, it is divided as follows: almost 100% in Italy, 50–70% in the UK, Denmark and Belgium, 15–30% in Spain, Germany, Portugal and France, and 0% in Switzerland. [2] In 2022, the UK industry recycled a record amount of waste wood, according to the Wood Recyclers Association (WRA). Annual statistics show that this figure increased from 4.17 million tonnes in 2021 to 4.31 million tonnes. [3]

By 2020, Ukraine has harvested about 17826.2 thousand cubic metres of wood [4], of which 17632.0 tonnes are wood waste [5], and exported 1.07 million tonnes worth $101.25 million.

For Ukraine specifically, it is very important to expand international economic cooperation, especially with the European Community. A huge step in the direction of waste wood (WW) is its use for energy. A significant increase in wood consumption for energy production in Ukraine is projected, up to 16.3 TWh/year in 2040 [6]. Adapting to European standards and high environmental standards for wood use can contribute to sustainable development and improve Ukraine's energy security.

The classification of waste wood is based on the degree of contamination of this resource. Based on the results of the analysis of scientific sources, it was found that the main classification criterion is the degree of contamination. The term "waste wood" covers industrial wood waste, including defective products, and used wood products.

Ukrainian scientists from the National Forestry University of Ukraine have developed a classification of waste wood (WW) that takes into account similar categories of waste in the European Union. This classifier offers four categories of waste wood with different degrees of processing and contamination:

– WW–I: This category includes solid wood and mechanically processed wood with minimal natural contamination and no halogenated compounds.

– WW–II: This category includes treated wood without protective agents and halogen–containing compounds in coatings.

– WW–III: This category includes treated wood without protective substances but with halogen–containing compounds in the coatings.

– WW–IV: This includes wood treated with protective substances.

In addition, the WW–PCB category has been defined to cover wood containing polychlorinated biphenyls (PCBs) and other harmful compounds that require special treatment. This classification helps regulate the management of wood waste and ensures the sustainable and safe use of this valuable resource.

The use of waste wood requires a careful approach to its processing and use. According to the developed concept, the first step is to analyse the content of chlorophenol, creosote grease and other harmful preservatives. After that, wood grades with high levels of contaminants are sent for heat treatment.

Depending on the category of WW, there are different options for managing this waste. Some waste wood is reusable, for example, railway sleepers can be partially reused.

Some material is selected for processing into chips for chipboard, while the rest is used for energy use.

The main categories of WW can be used to produce energy or secondary raw materials. For example, untreated wood is usually processed into secondary raw materials, while treated wood can be used as a source of energy.

In particular, the efficient use of waste wood helps to reduce waste and contributes to the creation of additional energy sources. Modern processing technologies make it possible to obtain various products from waste wood.

Recycling plants

Here are some companies that work with waste wood. One of them is the WRA (Wood Recyclers Association). It has more than 100 member companies representing more than 90% of waste wood recyclers in the UK. Through them, you can find out about wood recycling in the UK, who does it, what happens to wood during recycling, and where to go if you have waste wood to dispose of. The company also offered a summary of its wood waste estimates for the end of 2023 (below).

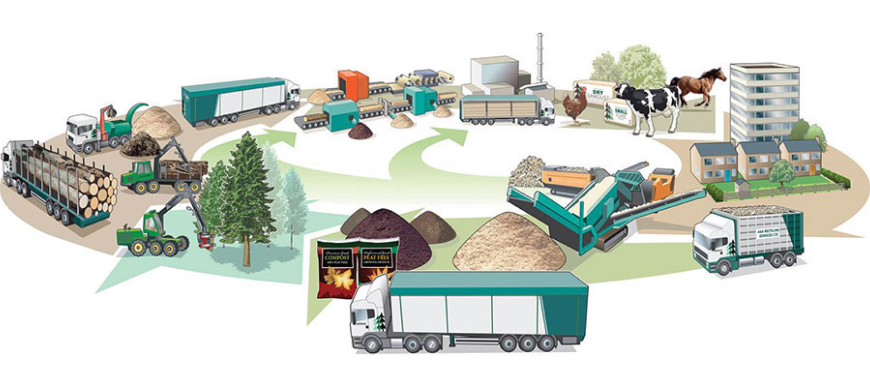

Another example of a waste wood company is A.W. Jenkinson Woodwaste. The company is actively involved in the processing of waste wood and organic waste at its Hespin Wood plant in Scotland. The plant, located north of Carlisle, is one of several facilities in the A.W. Jenkinson Group that specialise in organic waste processing. The company produces the following products:

– A–Grade Biomass

– Timber chip for board manufacturers

– Low–Grade Biomass

– Racehorse Gallop Surface

– Equine Arena Surface

– Cattle & Sheep Bedding

– Woodland Walkway Surface

– Dairy Cubical Bedding

Processing and utilisation of waste wood

Choosing the right system for processing and utilising WEEE can significantly reduce carbon dioxide (CO2) emissions. European countries analyse the level of WW utilisation by 3 systems: recycling, energy production and landfill disposal. Efficient use of WW in countries reduces the amount of material in landfills and stimulates competition for raw materials, which contributes to its efficient use.

Forecasting future trends in energy and economic development, experts conclude that fossil fuels can be replaced by renewable energy sources. The use of energy generated from railway transport can significantly reduce CO2 emissions compared to the use of coal or oil. This approach is important in the context of combating climate change and ensuring sustainable development.

Let's consider 3 scenarios of possible use of waste wood in Ukraine:

Scenario "Electricity generation and processing" – provides for the integrated use of WW, which reflects the current situation (gives average results, requiring moderate amounts of wood and coal for energy and processing).

"Electricity production only" scenario – focuses on the use of WW for electricity production only (provides the highest amount of useful energy but requires the largest amount of fresh wood).

Maximum processing scenario – focuses on maximising the use of WW for processing, but not more than 80%, leaving 20% for other purposes (provides the least amount of useful energy, but does not require additional fresh wood).

These scenarios identify ways of using WW for energy production and processing, taking into account limited resources and technological capabilities. The scenarios also have different implications for greenhouse gas emissions, coal and wood requirements for energy and processing.

Taking all of the above into account, it is clear that it is important for Ukraine to develop a system of waste wood management based on scientific research and global standards.

Resources

[1] Wood waste in Sweden (https://xylorevolution.com/2–million–tons–of–wood–waste/)

[2] A Decision Tool for the Valorization of Wood Waste (https://www.researchgate.net/publication/376330131_A_Decision_Tool_for_the_Valorization_of_Wood_Waste)

[3] Record set for waste wood processing (https://www.mrw.co.uk/news/record–set–for–waste–wood–processing–29–06–2023/)

[4] Wood production by type of forest product by region of Ukraine (https://ukrstat.gov.ua/operativ/operativ2020/sg/lis/lis_reg/arh_zdvp_reg_u.htm)

[5] Generation and management of hazard classes I–IV waste in Ukraine by material category in 2020 (http://www.kyiv.ukrstat.gov.ua/p.php3?c=3428&lang=1)

[6] "EFFICIENT USE OF USED WOOD AS A BASIS FOR REDUCING CO2 EMISSIONS" Assoc. Prof. S.V. Gaida, PhD in Engineering – National Forestry University of Ukraine, Lviv

[7] Wood Waste: Recycle, Bury, or Burn? Jeffrey Morris Gives an Answer. (https://zerowasteeurope.eu/2016/09/wood–waste–recycle–bury–or–burn–jeffrey–morris–gives–an–answer/)

Leave your feedback Cancel reply